Sorter System

Sorter System

At Inlog Robot, we are proud to introduce our next-generation cargo sorter systems, engineered to transform the way you handle parcel distribution and optimize warehouse efficiency. Designed with precision manufacturing, advanced imaging technology, and intelligent control software, our sorter solutions directly address the growing demands of modern e-commerce and logistics operations. Backed by years of industry experience and a commitment to innovation, we deliver systems that accelerate throughput, minimize human error, and bring unprecedented visibility and control to your fulfillment workflow.

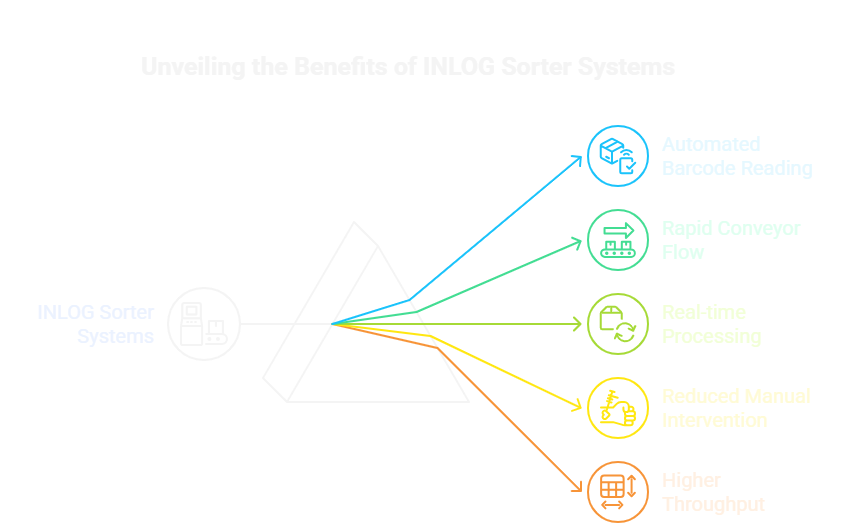

Optimize Operational Efficiency: INLOG Cargo Sorter systems are engineered to maximize efficiency in warehouse sorting operations. With camera-assisted barcode reading, real-time control software, and high-speed conveyor flow, the sorter significantly accelerates the parcel separation process compared to manual methods. This increase in speed and accuracy allows businesses to process more orders simultaneously. By reducing manual handling, your workforce can focus on higher-value tasks, improving overall operational productivity.

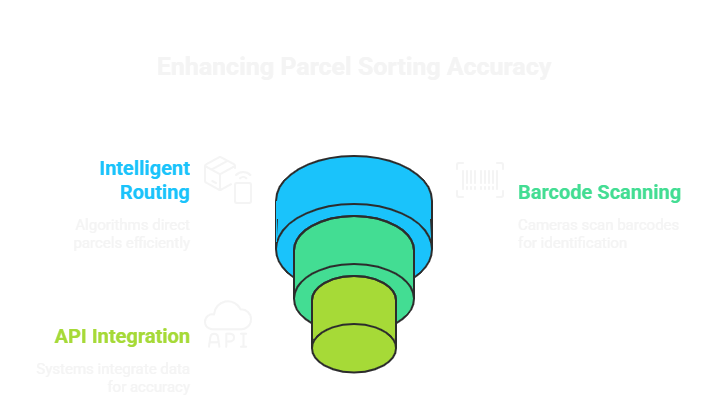

Reduce Sorting Errors with Intelligent Routing: Our sorter utilizes intelligent routing algorithms that automatically read each parcel and direct it to the correct output lane. With seamless bidirectional API integration to WMS/ERP systems, the sorter captures parcel numbers, routing data, and carrier information with precision. This drastically lowers misrouting rates, increases customer satisfaction, and minimizes loss or return-related costs. Every parcel’s movement—whether it entered the system, passed through the sorter, or which exit it was directed to—is fully traceable and stored.

Data-Driven Performance Optimization: Minute-by-minute, hourly, daily, monthly, and yearly performance reporting empowers users to deeply analyze sorter productivity. Real-time graphs reveal peak times, slow periods, and operational bottlenecks. This data allows businesses to refine staffing levels, improve throughput planning, and optimize overall performance—turning the sorter into a strategic decision-making tool rather than just an automated machine.

Maximize Workflow Visibility: The INLOG sorter system delivers full operational visibility through its web dashboard, desktop control application, and SCADA interface. Real-time parcel flow, exit-based distribution, performance analytics, error logs, and energy consumption data can all be monitored from a single platform. This level of transparency enables instant operational decision-making while providing management teams with valuable insights for performance optimization and capacity planning.

Increase Reliability with SCADA-Based System Monitoring:

The sorter solution continuously monitors all conveyors, sensors, motors, and safety components through a robust SCADA infrastructure. System status, emergency stop signals, conveyor faults, camera connection states, and PLC communication are instantly displayed to the operator. Issues can be detected early, minimizing downtime and allowing maintenance teams to respond quickly. Reliability and operational continuity are core strengths of the INLOG sorter architecture.

Real-Time Photo Archiving for Quality and Security: Every parcel passing through the sorter is captured with time-stamped photos and automatically archived. These visual records provide strong evidence in cases of lost, damaged, or disputed shipments, while also increasing transparency across logistics workflows. The daily folder structure allows users to quickly review past operations. Your system benefits from not only digital records but also physical visual evidence of every parcel processed.

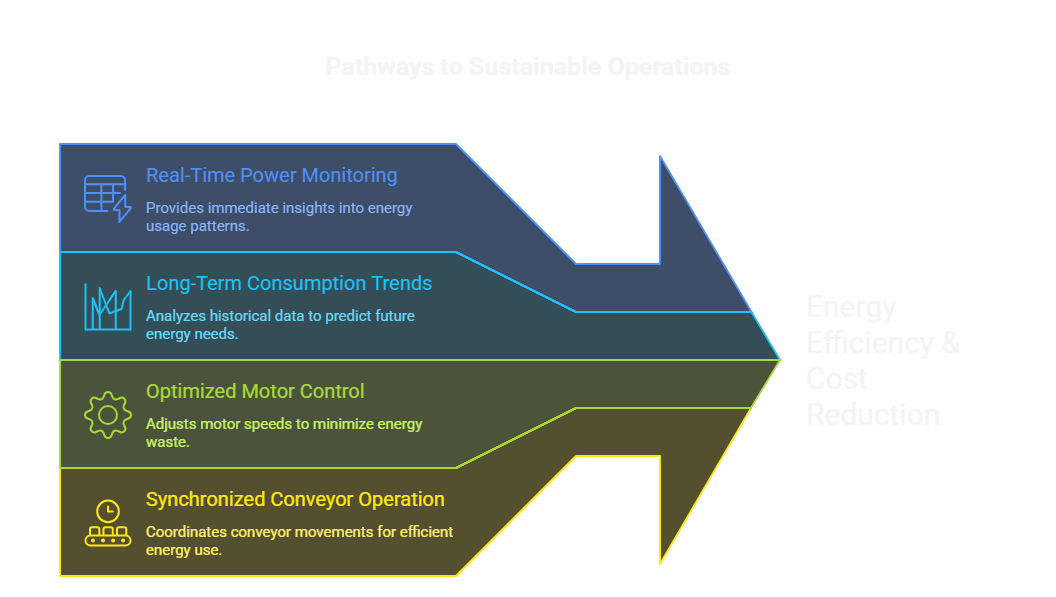

Improve Energy Efficiency and Reduce Operating Costs: INLOG sorter systems include an integrated energy monitoring module that tracks active and reactive power consumption in real time. By analyzing consumption patterns and eliminating unnecessary loads, companies can significantly reduce electricity costs. The system’s optimized motor drivers, synchronized conveyor control, and low-friction mechanical design contribute to long-term energy savings. Detailed energy reports can be exported for auditing, budgeting, and sustainability initiatives.

What Does the Sorter System Offer You?

- Increased Efficiency

- Improved Sorting Accuracy

- Enhanced Traceability & Visibility

- Streamlined Workflow

- Enhanced Operational Safety

- Energy Efficiency & Cost Reduction

- Scalability and Flexibility

Increased Efficiency

While the initial investment in shuttle systems may be significant, the long-term cost savings can be substantial. By reducing labor costs, optimizing energy consumption, and improving operational efficiency, shuttle systems can lead to significant cost savings over time, ultimately improving the bottom line.

Improved Sorting Accuracy

Intelligent routing algorithms, camera-based barcode scanning, and WMS/ERP API integrations ensure parcels are directed to the correct output every time. This minimizes misroutes, reduces returns, and improves customer satisfaction.

Enhanced Traceability & Visibility

Every parcel processed through the sorter is recorded in detail — including barcode data, time stamps, routing output, and photo archiving. Real-time dashboards and SCADA monitoring provide full operational visibility from any screen.

Streamlined Workflow

By automating repetitive sorting tasks, your workforce can focus on value-added operations. The sorter optimizes overall workflow, reduces congestion, and keeps your fulfillment processes running smoothly at all times.

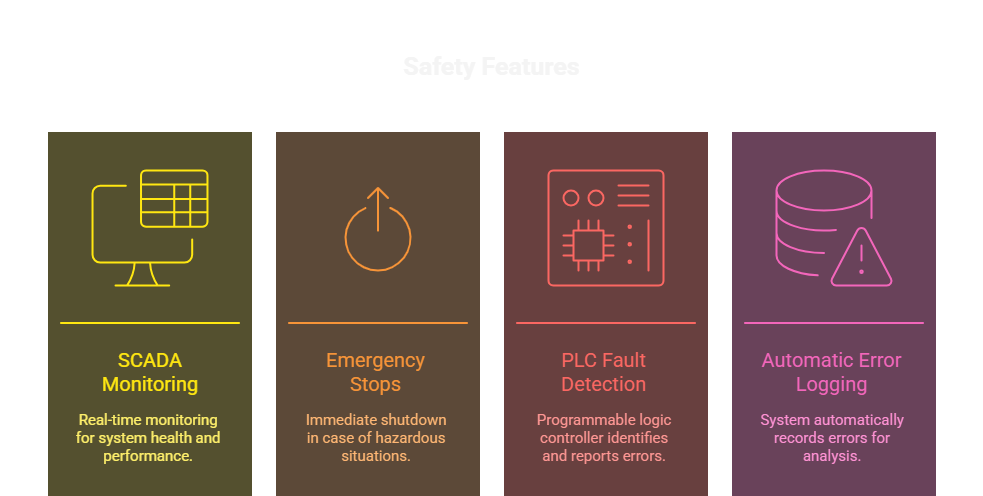

Enhanced Operational Safety

With SCADA-based monitoring, emergency stop controls, PLC-level fault detection, and automatic error logging, sorter systems enhance workplace safety and reduce the risk of manual handling incidents.

Energy Efficiency & Cost Reduction

The integrated energy monitoring module reports real-time power usage and long-term consumption trends. Optimized motor control and synchronized conveyor operation help reduce electricity costs while maintaining consistent performance.

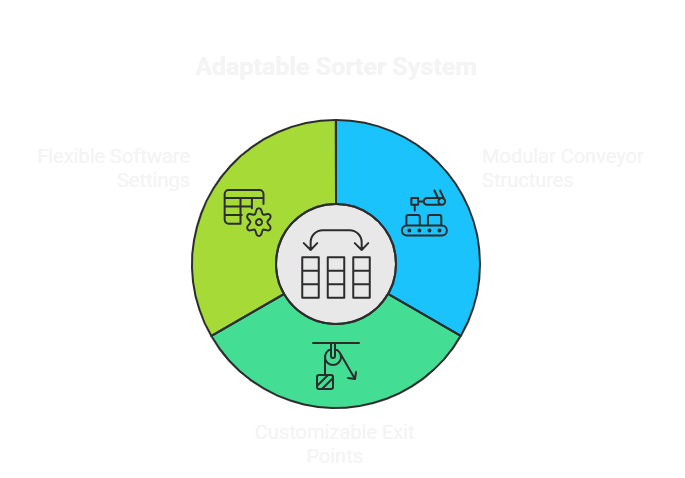

Scalability and Flexibility

Sorter layouts can be tailored to operational needs — from small facilities to high-volume fulfillment centers. Modular conveyor structures, customizable exit points, and flexible software settings allow the system to grow with your business.

Real-Time Scanning

Operational Visibility

Sorter System

Intelligent Routing

Flexible Integration

High-Speed Sorting

Energy Efficiency

System Reliability

99%

Operational Uptime